Biodigesters - Facts - Figures

What is a Biodigester?

A Biodigester simply means a tank which digests organic material biologically. In this sense, the FilterPod is a biodigester.

However, many people think of a biodigester as a tank which digests, anaerobically, without air, organic material and produces methane gas for cooking, lighting and heating ect.

The composition of the gases produced by this type of biodigester is about 60% Methane, 30% Carbon Dioxide and the rest is Hydrogen Sulphide.

However, for a Biodigester to produce enough methane to make it practical for cooking alone, it would require all the household waste and toilet waste plus more manure from large farm animals. The Intergovernmental Panel on Climate Change (IPCC) estimates that an average biodigester tank produces 25.5 g of methane per user per day, which is not enough even for cooking a one-pot evening meal. As most UK households do not keep cattle or pigs, small scale Biodigesters are not practical in the UK.

Biodigesters are, however, superb solutions for rural agrarian communities, intensive livestock farms, towns and cities where the large volumes of domestic and animal wastes can produce significant quantities of methane. In rural areas, biodigesters are built in settlements where there is adequate animal manure. In Indian villages larger units are made to serve a number of families or even a whole village. In China, where most rural families keep numerous pigs, the one family unit is common.

To produce 1 m3 of BIOGAS, to cook 3 meals daily for a small family of 4 you need at least 5 litres of pig manure/day. 8 large pigs (breeding adults) will produce 5+ litres/day.

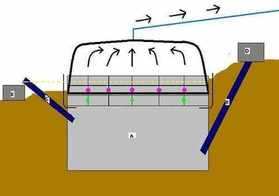

An example of a simple biodigester for animal manure is shown below.

A simple home-made family Biodigester System

'A typical simple biodigester is shown above. A is the biodigester tank where a water and manure mixture is digested by methane producing anaerobic bacteria. Cow manure is a lot more fibrous than pig manure, therefore the dilution rates are different. If human and cow manure is being used in a biodigester of this size (1.9 meters deep X 1.5 meters wide X 3 meters long), you need to add 40 litres of water and 20 litres of manure every day. When working with pig manure you add, 20 litres of water for the same 20 litres of manure.

In the picture B and C represent the entrance and exit pipes respectively. The entrance tube should enter the tank near the bottom and the exit tube should enter the tank just beneath the first row of cement block. D and E represent the mixing tub and the collection tub respectively. The mixing tub will ideally be more than 60 litres in volume in order to mix the water and manure thoroughly. The mixture should have a uniform consistency to help optimal digestion throughout the tank. Also, in the picture, the green circles represent the bottom support pins that catch the frame of the plastic in case the water level decreases drastically. The purple circles represent the top hangers against which the frame of the plastic rests as it tries to float up to the water surface. The curved tubes that enter the tank on each end are to hold the mixing rope. The mixing rope is to have 4 litre jugs half-full with sand attached. When two people tug back-and-forth on this mixing rope for a few minutes daily, the partially submerged jugs break up any thick film that may gather at the surface, suffocating the bacteria in the tank below. The dotted yellow line represents the liquid level. Notice that the level comes right up to the rim of the exit tube. This parity is important, as every day that you put in 60 litres of mixture, the exit tube, in theory, will discard the same volume into the collection tub to be used for fertilizer. The black dome that hovers over the tank is the plastic frame that fits just under the top hangers (purple circles) and holds the plastic that balloons up when the biogas, represented by the upward arrows, bubbles up from the surface of the water/manure mixture. The biogas then escapes through the PVC tubing represented by the blue line that extends above the middle of the plastic. Through this tubing the biogas is transported to the kitchen to be burned for cooking.'

As you can see, you need a lot of pigs to make the methane for a single house!

The limitations for small Biodigester solutions in the UK are as follows:

1.A household which does not keep large livestock will not have enough nitrogenous organic material to make a biodigester worth installing.

2.The optimal temperature for a biodigester to work properly is 38°C This is difficult to achieve in the UK.

3.The organic material passing through is not heated enough to totally destroy all disease causing pathogens. A small percentage of the eggs of some cattle and human diseases may collect in the sludge.

4.Biodigesters produce a highly flammable and toxic gas, therefore it is essential that at least one member of the family is thoroughly conversant with the system and capable of immediate repairs.

5.Modern cleaning products, bleaches, antibacterials, etc. kill the anaerobic bacteria in the biodigester. This is not a great issue in developing countries, but is a much greater one in the UK.

At the moment, there is not a small scale biodigester available for purchase in the UK, though the technology may be viable for equestrian households, dog boarding kennels, smallholdings and families with a large, continuous amount of garden waste material.